nocred

Contaminated wastewater produced during hydraulic fracturing, or fracking, is a major environmental concern associated with natural gas extraction. Fracking involves pumping large amounts of water into underground rocks to release the natural gas stored within. When this water returns to the surface, it brings with it contaminants, including oils, salts, and heavy metals.

Natural gas companies typically deal with wastewater by pumping it back into the ground, but this process is expensive and raises concerns about geologic instability.

A team of Penn engineers is proposing an alternate solution: nanostructured membranes that filter a broad range of contaminants from wastewater.

Daeyeon Lee, an associate professor in the Department of Chemical and Biomolecular Engineering in the School of Engineering and Applied Science (SEAS); Kathleen Stebe, a professor in the Department of Chemical and Biomolecular Engineering at SEAS; Shu Yang, a professor in the Department of Materials Science and Engineering at SEAS; and Satish Kumar of the University of Minnesota are the recipients of a National Science Foundation “Scalable Nanomanufacturing Award” for their innovative proposal to clean up wastewater. The grant provides the team with $1.3 million over the next four years to refine their nanomembrane design and develop scalable production methods.

Nanomembranes—filters that can separate liquids and gases on a molecular scale—are already used in desalinating water. But purifying wastewater, which contains a suite of different contaminants, is much more challenging than removing salt.

“The oily compounds in fracking wastewater will completely degrade the performance of a traditional membrane,” says Lee. “Shu was already working on filters that repel oil, so it was very natural for us to get together and think about how we can generate membranes that separate both oil and heavy metal ions to ultimately recycle the water.”

Yang’s unique design—stringy nanoparticles deposited onto porous mesh—produces a textured membrane that effectively repels oils. The group hopes to refine this design into a product that is both highly selective in what passes through, and highly permeable so that large volumes can pass through quickly.

Applications of the team’s nanomembranes go beyond wastewater treatment. Membranes that can handle the profile of chemicals in fracking water could be used to make ocean water—also rich in oils, salts, and heavy metals—fit to drink.

“There are many potential applications of the membrane we’re fabricating,” says Yang. “Having the opportunity to translate our knowledge from small-scale lab explorations to large scales is very exciting.”

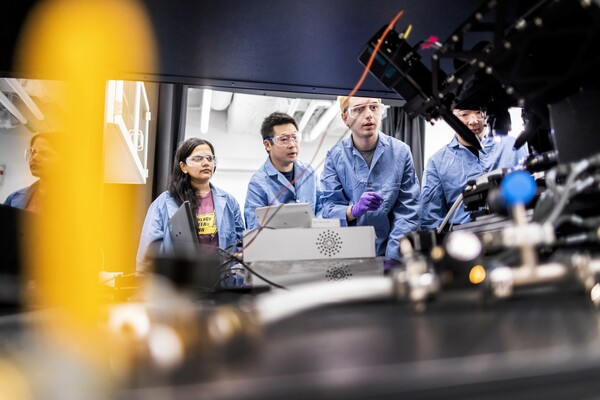

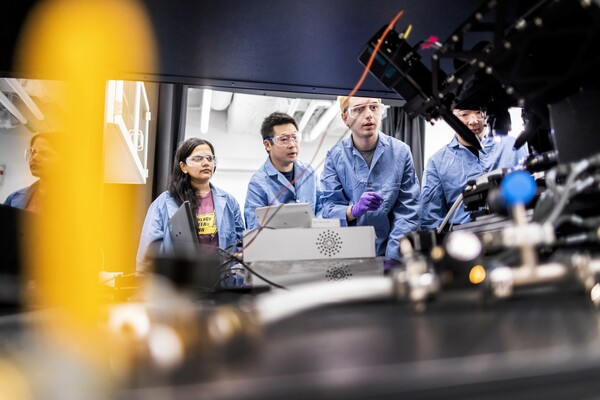

The team brings wide-ranging skills to their project, including expertise in fluid mechanics, biopolymer interactions, and material design.

“Our team is like a beautiful marriage,” says Stebe. “We have lots of complementary ideas, and we each sit in different spots in terms of our thinking. This is an exciting opportunity for us to take some of the basic research we do and do some good for society.”

Madeleine Stone

nocred

Image: Pencho Chukov via Getty Images

The sun shades on the Vagelos Institute for Energy Science and Technology.

nocred

Image: Courtesy of Penn Engineering Today