nocred

As one metal plate approaches another, pushing with a precise level of force, a small, white spiral of gypsum powder sandwiched in between the two pushes back. Just over an inch tall, the object finally succumbs to the pressure, a defined crack splitting it in two.

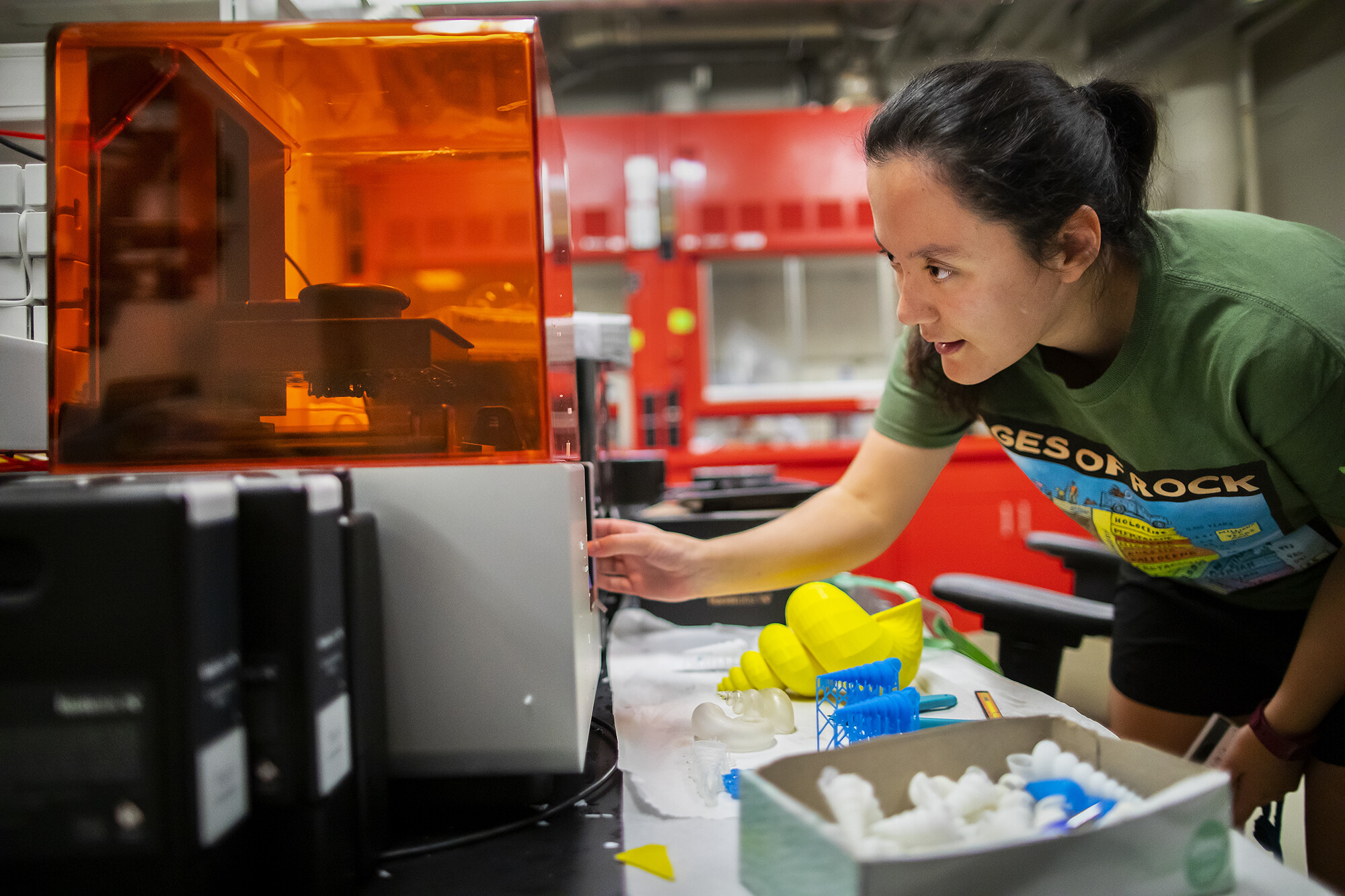

Breaking the object—a replica of a snail shell produced from a 3D printer in Hayden Hall—was the point. Erynn Johnson, a doctoral student in Penn’s Department of Earth and Environmental Science in the School of Arts and Sciences, is a paleoecologist interested in better understanding ancient marine ecosystems and what they tell us about future ecological changes on Earth. She’s employing 3D printing as a technique for recreating shells that resemble those in existence a couple hundred million years ago, and she’s testing them under various pressures to replicate the imposing jaws of a predator, such as a fish. Stronger shells mean a snail may have been more likely to survive the crunch.

“In paleontology, we can only infer based on what remains,” says Johnson, who is advised by Peter Dodson, a professor of anatomy and paleontology with appointments in the School of Veterinary Medicine and School of Arts and Sciences. “In particular, when you look at things that eat shelled organisms, like clams or snails, if the predator is successful the shell gets destroyed. So, it’s hard to infer what successful predation looked like—it’s actually easier to infer what failed predation looked like.”

Though still a student, Johnson, who is entering the final year of her degree program, is nevertheless among the pioneers of the use of 3D printing to study ancient predator-prey interactions.

She says that “3D printing has been applied for a long time in other fields, but it’s something that’s been underutilized in paleontology.”

When Johnson started out, she began by consulting with the Biomedical Library and its 3D-printing equipment. But the lab has since acquired a 3D printer of its own, with support from the department’s Greg and Susan J. Walker Endowment, to speed the work along.

Johnson’s background makes her a unique fit for her line of research. As an undergraduate at Cornell University, she was an earth science major with an interest in paleontology but worked diligently on a math minor as well. In a class with her undergraduate thesis advisor, he mentioned how paleontologists had begun applying mathematical models to understand shells.

“I remember thinking that was really cool,” she says.

Tweaking one of the variables in an equation that describes a shell’s shape, she learned, could mean the difference between a clam, a snail, or an ammonite, a type of extinct cephalopod.

“I realized that you could take something that had been stuck in a rock for millions of years, do some modeling, and recreate an ecosystem that no one had ever seen,” she says.

At Penn, supported by a National Science Foundation graduate research fellowship, she found the resources she needed to take these models even further, pursuing experimentation on the creations the models predicted. She’s particularly focused on a period from 250 million to 65 million years ago known as the Mesozoic Marine Revolution, when more dominant predators, including those capable of crushing shells, emerged.

“My hope is by studying this period where we had a major change in predator-prey relations, we can get better predictions about what will happen if we disrupt ecosystem dynamics in the future,” she says.

In setting up her experiments, Johnson has carved out her own path, while seeking advice from a wide range of sources. In addition to Dodson, her advisor, and Aja Carter, a fellow member of the Dodson lab, she’s sought advice from the department’s Douglas Jerolmack, a geophysicist whose work in a very different area—sediment transport—relies similarly on experimentation that requires the isolation of a single variable. Her goal is to isolate the effect of shape alone on a shell’s ability to withstand a crushing force.

She’s also sought technical input from staff at the Biomedical Library and from fellow graduate students at the School of Engineering and Applied Science, where she also occasionally uses space for her experiments.

Together with Carter, who has used 3D printing to re-envision the vertebrae of long-extinct quadrupeds, Johnson developed and co-chaired a session at last year’s national meeting of the Geological Society of America on 3D methods in paleontology. Johnson also received an award for best student talk at the conference from the Society’s Geobiology and Geomicrobiology division.

“We’ve done a lot of troubleshooting because when something goes wrong there is no one you can really ask; no one has done this before,” says Johnson. “Everything I do needs to be breakable, but the printers are designed to produce things that are difficult to break. One type of material is more brittle, but you can’t make certain shapes with it. We spend a lot of time figuring things out.”

While she’s still following up on a number of lines of inquiry, her preliminary results all tell her one thing: shape matters.

“This was the first study that solely looked at shape, without accounting for the shell’s microstructure, and we found that shape does matter all by itself.”

In addition to her research, Johnson also has a passion for education. She’s served as a teaching assistant (TA) for a few courses and has trained TAs through Penn’s Center for Teaching and Learning as well. This year, she was selected by the Center as a teaching fellow, helping to craft the workshops that TAs take to improve their skills.

After finishing her Ph.D., Johnson plans to continue her research but hopes to keep a foot in education as well.

“Paleontology is a nice gateway for getting people interested in science,” she says.

Katherine Unger Baillie

nocred

nocred

Despite the commonality of water and ice, says Penn physicist Robert Carpick, their physical properties are remarkably unique.

(Image: mustafahacalaki via Getty Images)

Organizations like Penn’s Netter Center for Community Partnerships foster collaborations between Penn and public schools in the West Philadelphia community.

nocred